Introduction

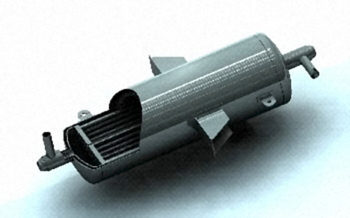

Static mixers are used for a wide range of applications including mixing, heat exchange and dispersion, due to numerous unique innovations our products are especially suitable for hygienic processes where CIP (cleaning in place) is required, and also a broad range of temperatures and viscosities.

Static mixers and Heat Exchangers can be designed to meet your specific requirements our team of engineers will be pleased to help with your application to ensure optimum process performance.

Applications

- General chemicals - agri-chemicals, paint, slurries.

- Polymers - polyesters, nylons, ethylene's, silicones adhesives, sealants

- Food & Beverages - sauces, chocolates, dairy products, salad dressing, sugar syrups.

- Energy - petrochemicals, fuel oil

- Pulp & Paper - Kraft soaps, black liquor, oils.

- Waste water treatment applications

Product design & development

All of our new products are designed using the most advanced CAD 3D modelling systems by our team of experienced application and CAD design engineers.

|

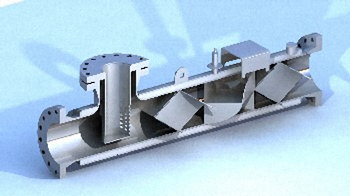

Technical profile Static Mixers basically consists of a set of serially placed twisted, helically shaped elements with a pitch of 34°. After a rotation of 180°, a new rotation starts in reversed direction. Each leading edge of the succeeding element is rotated 90° from its predecessor. Euromixers - Primix static mixers can be constructed with diameters ranging from 3.5 mm up to 2,000 mm. |

| The Quatro static mixer Construction of the quarto element is comparable to the standard helically shaped element, but it is manufactured by bending a flat metal strip and grinding afterwards, to the final shape and diameter. The finished profile depends on the diameter. |

|

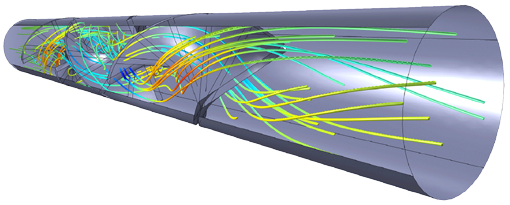

Laminar flow

Flow through the static mixer element is diverted into two separate streams. Optimisation of the profile induces equal radial and axial flow, the helix pitch creates a rotation of the fluid, by which the fluid flows from the outside to the inside and reverse. The differences in velocity that occurs creates a shearing of the fluids.

| After one rotation through the static mixer element a second diversion takes place and simultaneously a reverse of the succeeding rotation in the next mixing element occurs. |  |

As the number of streams or layers increases, the layer thickness decreases.

After only 20 rotations in a 50mm diameter Static mixer, mixing at molecular level is achieved 20 diversions of the fluid creates 220 separate layers, each 0.05 micron thick.

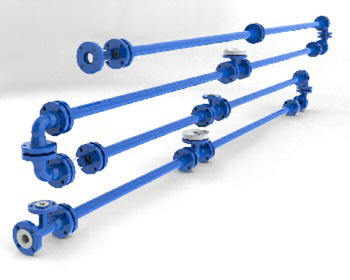

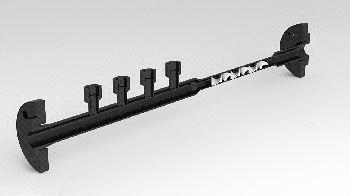

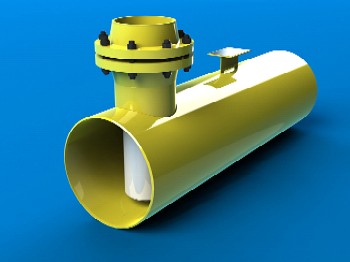

Picture gallery

The following pictures illustrate the diverse range of configurations available, our engineers will be pleased to help with your application.

|

|

|

|

|

|

|

|

Please contact our application engineering team we will be pleased to help with your application.

| Tel : +44 (0) 161 486 5099 Fax : +44 (0) 161 486 5031 Email : sales@euromixers.co.uk |

English

English French

French German

German Dutch

Dutch Russian

Russian Polish

Polish